CONCRETE

Concrete Foundations

Concrete foundations provide a stable base for structures by distributing loads to the ground. Key types we install are pile caps, spread footings, continuous footings, and equipment foundations. Each is designed to meet specific project needs, such as supporting columns, walls, heavy machinery, or addressing soil conditions.

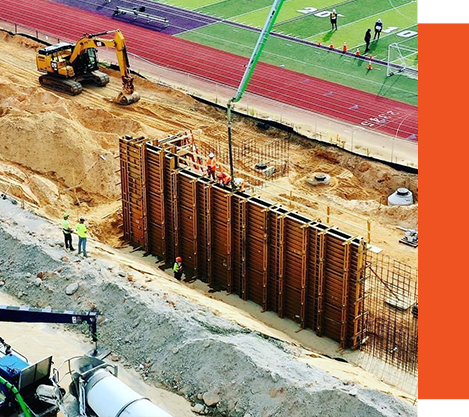

Deep Pits

Large industrial deep concrete pits involve shoring, excavation, and forming, to create durable, precise structures for underground systems. Our extensive experience with a variety of deep pit installations assures safety, scheduling, and end goals achieved.

Equipment Foundations and Cast In Place (CIP) Tanks

We meet our customers’ specific concrete requirements for their products, productions and equipment. We excel in meeting the challenges of large equipment foundations and CIP tanks with tight tolerances and specialized concrete specifications.

Cast in Place Vertical Walls and Structures

Our experience in vertical concrete walls and structures allows our clients to provide durable long-term solutions for their facilities. Our engineering team provides forming and shoring plans to execute a safe, long-lasting structure. We have decades of experience from our office to field teams with all facets of vertical concrete construction utilizing multiple forming systems.

Cast in Place Retaining Walls

Cast In Place retaining walls are often a separate specialty for civil contractors that are subcontracted out. Heycon can provide turnkey solutions from layout, excavation, forming, and backfill for large and small CIP retaining walls. This allows clients to have one point of contact throughout the project for site work and concrete.

Mass Concrete Placements

Our projects often require large monolithic concrete placements (aka mass pours) to ensure a joint free structure for the engineering necessary to support the required loads. This poses a risk of weakening or cracking during curing due to the added heat in the core of the mass pour. Our in-house team designs mass pour solutions to combat excessive heat transfer in the core of large concrete placements. From engineering cooling systems to mix designs and hot weather practices, we can meet and exceed the required mass pour specifications from ACI.

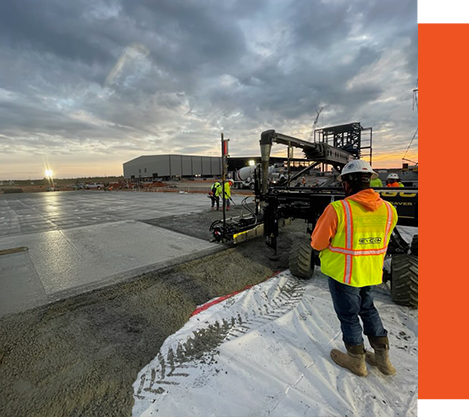

Laser Screed Slab on Grade

Laser screed slab-on-grade is a method used to achieve precise, level concrete surfaces for floors, utilizing a laser-guided machine to ensure accurate leveling and smoothness. Our process involves placing and finishing the concrete slab by first pouring the mix, followed by leveling, smoothing, and troweling to create a durable, high-quality surface suitable for various industrial, commercial, or residential applications. This technique ensures efficiency, precision, and a consistent finish for large-scale slab projects. We can meet and exceed tight FF/FL specifications for our customers.

Exterior Concrete Paving

Exterior concrete paving involves the installation of durable, high-quality concrete surfaces for outdoor areas such as driveways, parking lots, sidewalks, and roadways. Our process includes site preparation, forming, pouring, and finishing concrete to create a smooth, level surface that can withstand traffic, weather, and wear. We utilize 3D GPS equipment and laser screed for the placement of subgrade base materials as well as concrete to ensure top quality results.